Classic and Historic Vehicle Body Restoration Courses

About Us

Contour Academy was founded in 1998 with a mission to establish a centre of excellence for training in traditional sheet metalwork techniques.

Bruce Macleod has a wealth of experience gained from past generations of craftsmen and over 45 years involvement on a wide range of projects including: restoring and building steel and aluminium alloy vehicle bodies, forming stainless steel, copper and brass panels for automotive, marine and architectural applications as well as making sculptural artworks such as the copper petals for the 2012 London Olympic’s cauldron

On each course you are given a significant amount of one-to-one tuition using a wide range of equipment to ensure you get the maximum benefit from your learning experience with us.

Summer School

Five days - £1640

4th to 8th and 11th to 15th August 2025

Courses are held at Welford, Northamptonshire

Course overview

This course covers the fundamental principles of cutting, flanging, shaping and welding mild steel and aluminium alloy to form double-curvature panels as well as making patterns, jigs and tooling to replicate original parts.

Forming & Welding Mild Steel

- Shape a double-curvature panel using a mallet and block

- Smooth a panel using a hammer and dolly and wheel

- Use a wheeling machine to create a shaped panel

- Flange & wire the edge of a panel

- TIG butt-weld mild steel sheet without using a filler rod

- MIG weld and resistance spot weld mild steel

Forming & Welding Aluminium Alloy

- Form a complex double-curvature panel in aluminium alloy

- Refine and smooth a panel using a wheeling machine

- TIG butt-weld aluminium alloy sheet without using a filler rod

- Anneal aluminium alloy sheet

Making Patterns, Jigs and Tooling

- Take an accurate profile from the original bodywork

- Make a pattern to accurately reproduce an original panel

- Develope a pattern for a double-curvature panel

- Construct jigs to aid reproduction of double-curvature panels

- Use tooling to replicate original pressed detail

- Form a repair section that is a precise fit to the original panel

Enquire about courses

Please send enquiry for more information on our courses

Books

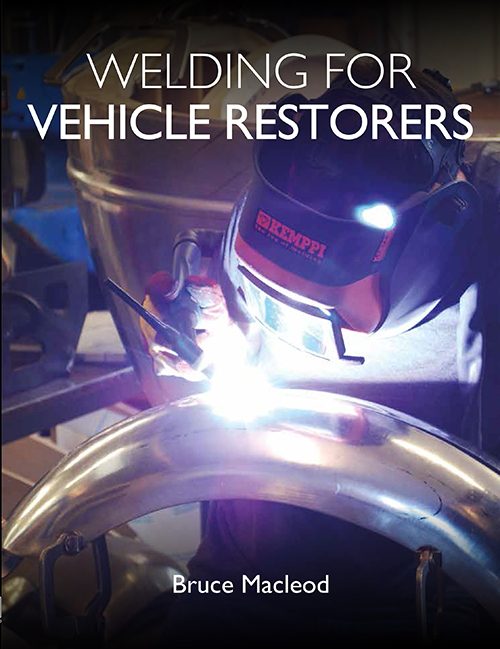

Welding

This book covers the various methods of welding used to make and repair sheet metal body panels. The techniques use in the welding of thin sheet metal as used on vehicle bodies are vastly different to those used in welding heavier structures.

I have set out to explain as simply as possible the methods, materials and equipment that I have found to be most useful.

The important thing for anyone wanting to achieve a good finish to body repair work is to start with the correct techniques, skill comes with practicing these techniques in the right manner.

The text of the book concentrates on the welding of mild steel and aluminium alloy with some reference to the welding of brass and stainless steel sheetmetal.

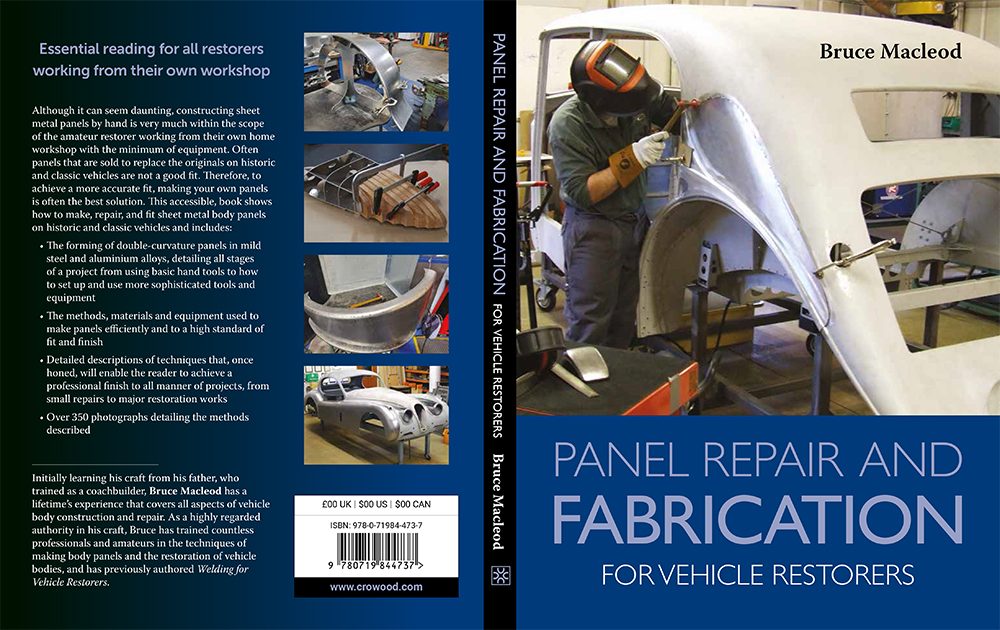

New release!

This book covers how to make, repair, and fit sheet metal body panels as used on Historic and Classic vehicles. The text covers the forming of double-curvature panels in mild steel and aluminium alloys, from using basic hand tools to how to set up and use more sophisticated tools and equipment.

Bruce also offers one-to-one mentoring and on-site training

📞 07880 290813

📧 bruce@contouracademy.com

© Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.